Power Station

Process | Gas Turbine

|

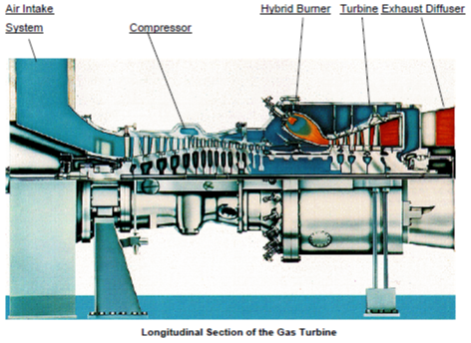

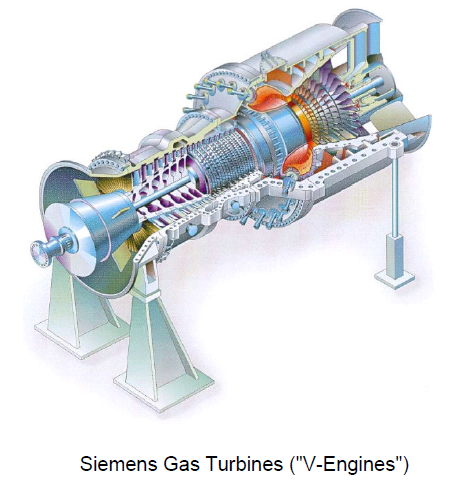

The model V94.3A combustion turbine is a single-shaft machine of single-casing design, burning natural gas. The rotor is supported by two bearings. A combined journal and thrust bearing is located at the inlet side of the compressor, and a journal bearing at the exhaust side of the turbine. The rotor is an assembly of disks, each carrying one row of blades, and hollow shaft sections, all held together by a pre-stressed central-tie bolt. Hirth serration provides the alignment of disks and hollow shaft sections to allow free radial expansion and contraction, and transmit the generated torque. The turbine rotor is internally air cooled. The ring-type combustion chamber is connected to the turbines common outer casing. The gas turbine has a uniform exhaust-gas temperature field over the full cross-sectional area of the diffuser. The design is based on extensive operating experience with hybrid burners since 1986. This combustion system combines all the advantages of optimal combustion, including

The gas turbine is factory assembled and shipped in modules for convenient field erection. |