Power Station

Process | Steam Turbine

|

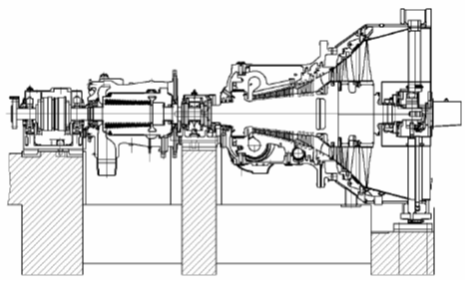

The steam turbines are modular constructed, are factory assembled and shipped in modules for convenient field erection. It is composed by one single flow HP turbine (H-Type) and one combined single-flow IP/LP turbine (E-Type). The rotors are designed with a single bearing system. This means that the shaft system has only one bearing between the two turbine casings. Journal bearings are arranged at both ends of the turbine. The individual turbine shafts are rigidly coupled together by means of integral flanges. Each turbine is fitted with combined stop and control valves for the HP, IP and LP- steam admission. The valves are equipped with an electro-hydraulic actuator. There is a common lubrication system for gas turbine, generator, steam turbine and clutch. The oil is supplied by an electrically driven main oil pump during normal operation. A synchronous clutch is located between the generator and the steam turbine and serves to transmit the torque to the generator shaft. The application of the clutch increases the operation flexibility and allows a faster start-up of the power plant. |